A Comprehensive Guide to AISI 1045 Medium Carbon Steel

AISI 1045 steel is known for its good welding, machining, features and high strength and impact resistance. It is utilized in tempering or induction hardening conditions to achieve surface hardness up to 60HRC.

What is the Melting Point of Titanium?

Titanium is a lightweight, high-strength metal known for its excellent corrosion resistance. Companies use titanium in aerospace, medical devices, and chemicals.

High Carbon Steel Knives: Pros and Cons

uality knives require both hardness and sharp edges. In this regard, high-carbon steel does the job. This article presents the data on why high-carbon steel knives are common and what are their drawbacks.

Alodine vs Anodize, A Comprehensive Comparison

Before starting the comparison between Alodine and anodize, you must know what actually are these? Well, these are two types of finishing for Aluminum.

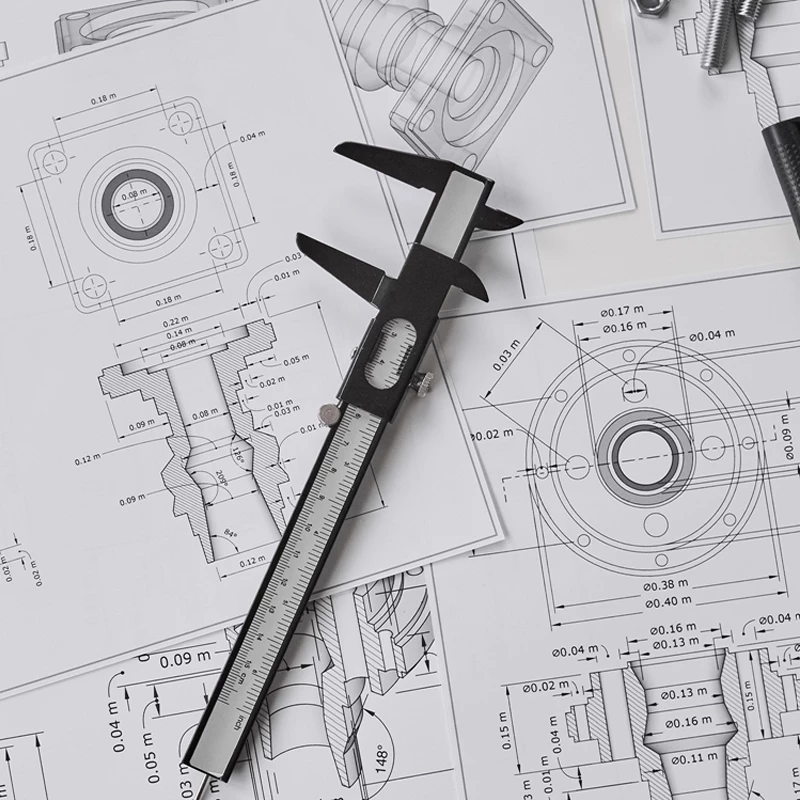

Understanding CNC Drawings and Related Concepts

CNC drawings are detailed blueprints that communicate specific instructions and specifications to machinists.

CNC Machining Thin Washers: A Comprehensive Guide

Thin washers are widely used in industries such as aerospace, automotive, and electronics. They may appear simple, but machining them to exact specifications requires precision and careful planning.

Black Anodized Aluminum: Your Ultimate Guide to a Superior Finish

Black anodizing services to aluminum provide a visually appealing surface and has high resistance and durability. This treatment is often used in industries to coat parts for better performance.

T651 Aluminum: 6061 and 7075 Properties, Uses, Difference

6061-T651 aluminum is a type of aluminum that is strong and simple to work with. It doesn&rsquo t rust easily, which makes it a beneficial choice for many applications. 6061-T651 as tough but flexible plastic.

Comprehensive Overview of CPM 10V Steel

CPM 10V steel is a high-vanadium tool steel. It is produced using Crucible Particle Metallurgy (CPM). This process results in a fine-grained microstructure. This enhances the steel’s wear resistance and toughness.

All About D2 Steel: Properties, Composition, and Knife Applications

D2 tool steel is a semi-stainless steel. In industrial tooling, specifically in custom knife making field, D2 steel stands out as a preferred material among manufactures and artisans.

Surgical Steel vs Titanium: Deep into the Properties, Piercings, and Suitability

stainless steel is the commonly used alloy in every field. It has superior strength and excellent corrosion properties. Similarly, titanium is also a comparable metal. It has similar strength to stainless steel has. But the strength to weight ratio is much less than steel. This means it is a lighter material and has the same features as stainless steel.

Zinc Plated vs. Stainless Steel: Which Material is Right for Your Application?

In the world of manufacturing and design, material selection is one of the most critical decisions you can make. The materials you choose will directly impact the performance, durability, and cost-effectiveness of your products. Two of the most commonly debated materials are zinc-plated steel and stainless steel.